PRODUCTS

MONO-ACETATE

These are also called standard filters and can be manufactured in all industry specifications. Other options include coloured plugwrap paper and/or coloured acetate tow providing more marketing and differientiation tools.

- Length range (but not limited to): 60mm – 150mm

- Diameter range (but not limited to): 5.00mm – 8.10mm

DUAL-CHARCOAL

These type of filters consist of combined segments of charcoal (activated carbon) and mono-acetate together. Both these segments of charcoal filters and mono-acetate filters are produced separately first and then combined on our high-speed combiner lines. Dual acetate-charcoal filters directly affects the cigarette taste and tar delivery improving the filtration making the cigarette smoother. It is a unique filter that can differentiate your brand of cigarettes from the others in the market. Although dual filters are mainly produced with charcoal/acetate, it can also be produced with combinations of other types of filters such as flavoured filters, capsulated filters, etc.

Capability: All industry specifications/segmentations using non-porous or porous plugwrap paper and in all formats: King size, queens, slims and superslims.

RECESSED

A more advanced version of dual filters. This type of filter has a unique mouth-end appearance with no direct contact with acetate tow. In other words, there is a gap or space between the charcoal and acetate segment. A typical segmentation of such filters would be: recess (gap) + acetate + charcoal. Recessed filters are mainly produced with acetate + charcoal but if required, we can produce with different combinations of other types of filters as well such as flavoured filters, capsulated filters, etc.

Capability: All industry specifications/segmentations using stiff plugwrap paper and in all formats: Kingsize, queens, slims and superslims.

TRIPLE SOLID

A multi-segmented filter rod with an additional recessed segment which creates uniqueness and an increased taste experience. It is a unique tool to help distinguish your brand among others in the market.

Capability: King size format with 108mm and 120mm length using non-porous/porous plugwrap paper. Any other specifications can be discussed.

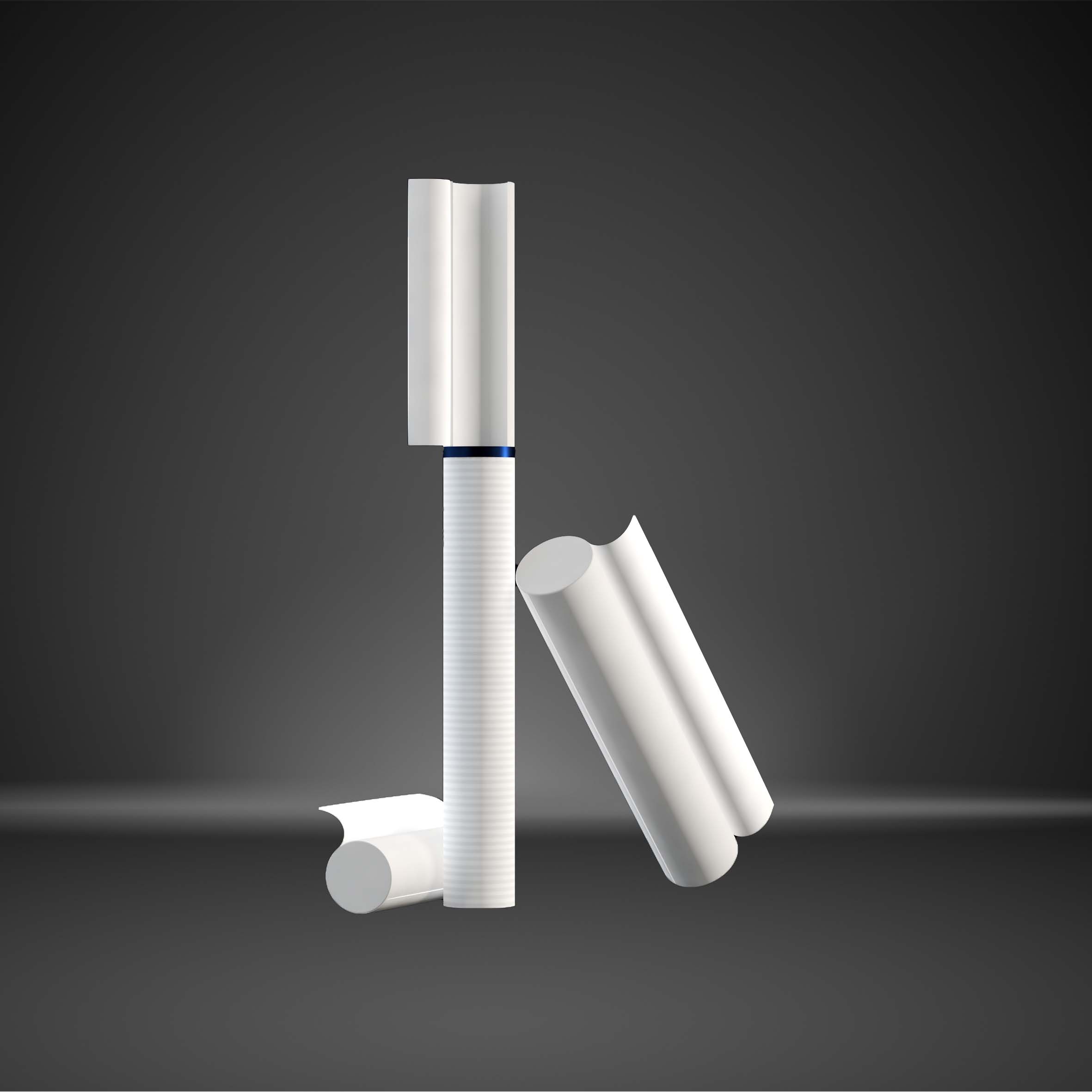

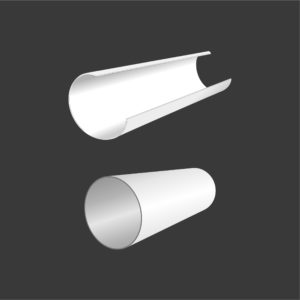

HOLLOW-TUBE

A new trend in the industry today and our newest capability. These filters have a hollow segment at the mouth end and are generally made using the NWA (Non-Wrapped Acetate) technology. Hollow filters are usually combined with acetate + charcoal segments but can also be combined with other types of filters. Typical segmentation would be: hollow + acetate + charcoal or hollow + acetate. However we can also supply Hollow filters on their own (without combining) if required.

Capability: All industry specifications and in all formats: King size, queens, slims and superslims.

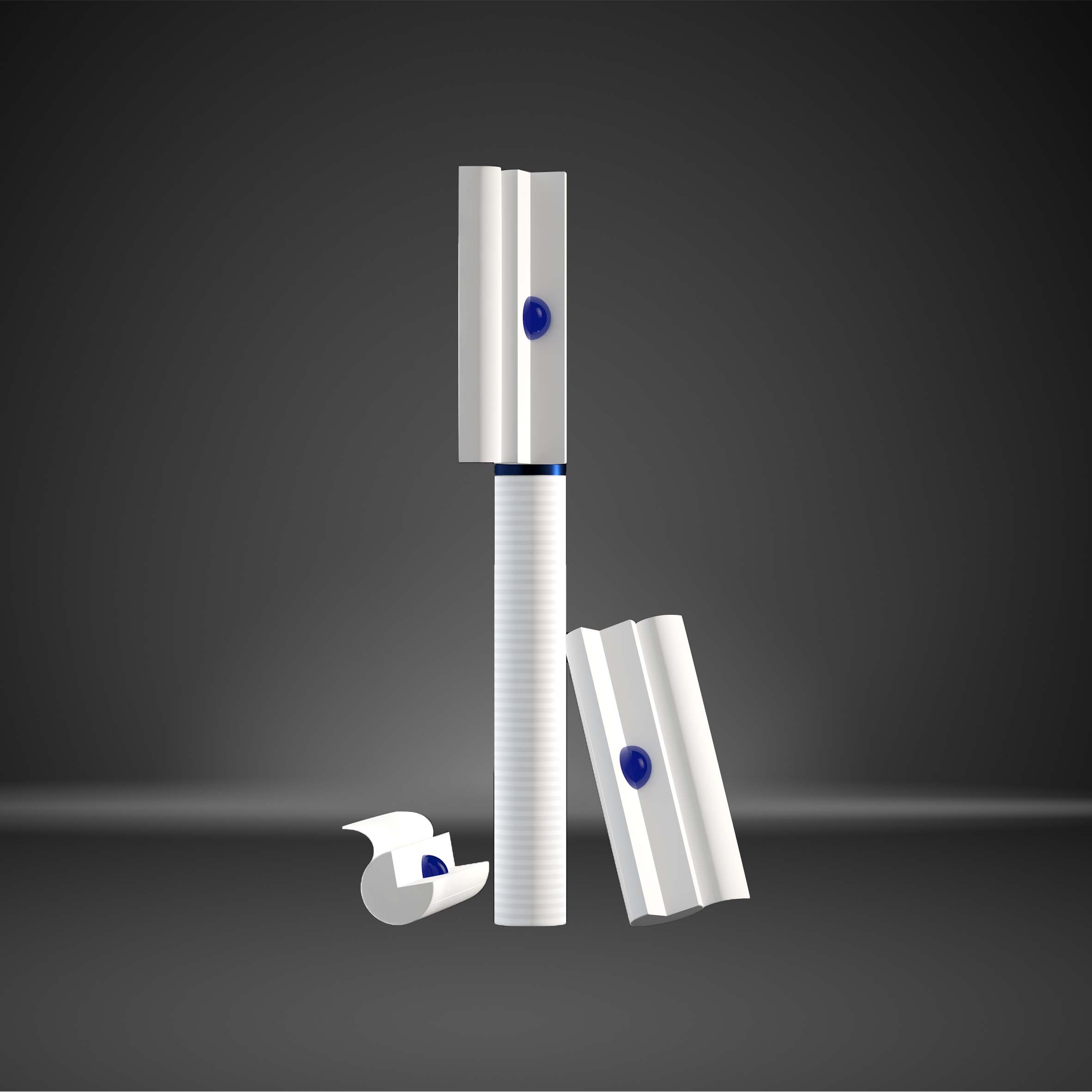

CAPSULATED

The industry always demands something different or innovative and ARD is geared up to respond to our partners’ requests with state of art technological capabilities. These are filters with a crushable flavoured ball/capsule and when crushed, the flavour spreads in the filter providing an overwhelming flavour experience to the smoker. The beauty of such filters is that the smoker has the option of crushing the ball/capsule whenever desired. It is ‘flavour on demand’. We have the pleasure of working with leading capsule suppliers with capabilities of providing any flavour desired in the capsule such as menthol, strawberry, chocolate, coffee, apple, cherry, mint and many others.

Capability: 1. Kingsize format available in 90mm (6up), 100mm (4up), 108mm (4up), 120mm (4up & 6up), 126mm (6up) 132mm (6up) 2. Superslims format available in 108mm (4up), 120mm (4up)

FLAVORED

The industry always demands something different or innovative and ARD is geared up to respond to our partners’ requests with state of art technological capabilities. These are filters with a crushable flavoured ball/capsule and when crushed, the flavour spreads in the filter providing an overwhelming flavour experience to the smoker. The beauty of such filters is that the smoker has the option of crushing the ball/capsule whenever desired. It is ‘flavour on demand’. We have the pleasure of working with leading capsule suppliers with capabilities of providing any flavour desired in the capsule such as menthol, strawberry, chocolate, coffee, apple, cherry, mint and many others.

Capability: 1. Kingsize format available in 90mm (6up), 100mm (4up), 108mm (4up), 120mm (4up & 6up), 126mm (6up) 132mm (6up) 2. Superslims format available in 108mm (4up), 120mm (4up)

HOLLOW PAPER

Some particular markets and/or brands require filters that are manufactured without the use of acetate tow. These hollow filters are produced using only stiff plugwrap paper. We can also use coloured stiff plugwrap paper.

Capability: All specifications and in all formats: King size, queens, slims and superslims you desire.

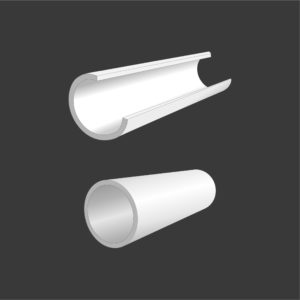

SHAPED

Speaking about innovation, shaped filters has been one of our recently achieved capabilities that can used as a great tool for differentiating your brand. These are hollow NWA filters with an inner shape embedded like heart, star, triangle or any other shape. Such filters can be supplied on their own or combined with other segments like dual-charcoal, flavoured, capsule, coloured filters, etc.

Capability: All specifications and in all formats: King size, queens, slims and superslims.

FILTER TIPS

We can also manufacture filter tips which are very popular in some markets and are required for RYO (roll-your-own) application. These are filter rods that are cut into small tips like 15mm, 17mm, 20mm, 25mm and the usual required diameter is 6mm (slims) and 8mm (kingsize). Other specifications can be manufactured.

Capability: All specifications and in all formats: King size, queens, slims and superslims.

At the moment, we can supply filter tips in bulk packaging however other packaging needs can be discussed.

MANUFACTURING & RESEARCH

MANUFACTURING PROCESS

At ARD Filters, filter production is taken very seriously with no room for substandard products. Our production process follows leading industry standards and is efficient in high-speed production without sacrificing quality and precision. We invest only in top-of-the-line machines that provide speed and accuracy, with specialized functions and flexibility for production tasks. Packed with state-of-the-art machines and manned by trained and skilled personnel, quality is constantly watched and supervised so that our brands that adhere to the highest quality standards.

RESEARCH AND DEVELOPMENT

R&D is at the very center of ARD Filters. Our approach is global, diverse and flexible, and fosters an open worldwide network which aims to provide innovative solutions which create value and makes us stand out from our competitors. Our dynamic international network of experts helps us to provide the finest technical support, improve the performance to achieve operational excellence, and to create and launch ground-breaking news.